The Ultimate Guide to Tech Packs in Fashion

Feb 5, 2026

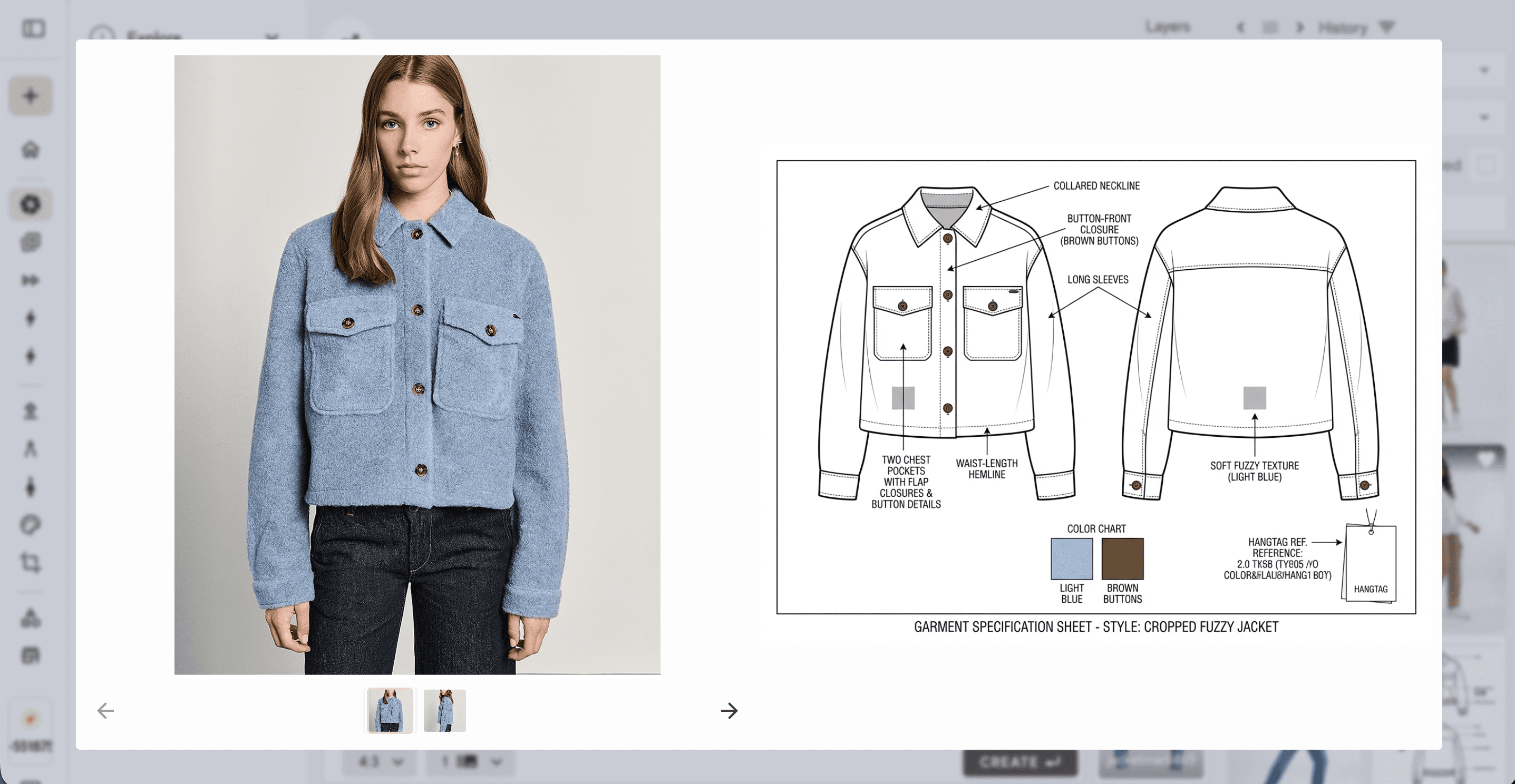

Fashion designers know the pain of seeing their vision muddled during manufacturing - costly mistakes, delays, endless headaches. Enter the tech pack: a detailed, no-nonsense blueprint for garment production, loaded with specs, measurements, materials, construction notes, and technical sketches that keep everyone on the same page from sketch to finished product.

Without solid documentation, even brilliant designs can end up lost in translation. Tech packs act as a universal language - they bridge that frustrating gap between creative ideas and actual products, cutting down on miscommunication and helping keep quality on track.

This guide digs into how to craft tech packs that actually make production smoother. You'll get the must-have components, some tried-and-true tactics for working with factories, and a look at how proper documentation can take your process from chaos to something that, dare I say, feels almost organized.

What Is a Tech Pack in Fashion?

A tech pack is a blueprint for garments - all the technical specs a factory needs to get production right. These docs are the go-between for designers and manufacturers, setting clear standards for how things should be made.

Definition and Purpose of Tech Packs

A fashion tech pack is a comprehensive document - think of it as the instruction manual for your garment. Designers use these packs to lay out exactly what they want, so manufacturers don't have to play guessing games.

The doc covers flat sketches, measurements, materials, and construction details. Tech packs minimize production errors and cut down on endless sample rounds.

Design Communication: Turns creative ideas into technical instructions

Quality Control: Sets clear standards for finished items

Cost Estimation: Gives factories what they need to quote accurately

Production Planning: Walks manufacturers through every step

Most professional factories require tech packs before they'll even start. No tech pack, no reliable results - simple as that.

Differences Between Tech Packs, Spec Sheets, and Production Manuals

People sometimes mix up tech packs and spec sheets, but they're not quite the same. Tech packs are more comprehensive documents - they bundle a bunch of spec sheets together and add more detail.

Fashion flat sketches from all the angles

Bill of materials - fabrics, trims, the works

Measurement specs with tolerances

Grading charts for sizes

Construction notes and stitch details

Spec Sheets are mostly about sizing and measurements charts galore, but not much else. Production Manuals are factory playbooks. They cover processes, standards, and workflows, but not the nitty-gritty of any single garment. Technical packs are the bridge creative vision meets manufacturing reality. They’ve got both the creative and technical sides covered.

Importance for Designers and Apparel Manufacturers

Designers count on tech packs to protect their ideas once things move to production. These documents ensure manufacturers understand every design detail from a quirky seam to a custom zipper pull.

For developers, tech packs make life easier. Everyone can track changes, manage feedback, and keep the chaos in check with one central doc.

Samples that actually match your concept

Fewer revisions, less wasted time

Cost estimates that aren't just wild guesses

Clear quality standards

Easy-to-follow instructions no guesswork

Material lists for sourcing

Specs for a proper fit

Notes to keep production consistent

Professional tech packs save both time and money by spelling out expectations early. They keep everyone honest, from first sketch to final shipment.

Core Components of a Tech Pack

A solid tech pack covers four big things: visuals of the design, a detailed materials list, clear construction instructions, and exact sizing info with grading rules. Miss one and, well, good luck with production.

Fashion Flat Sketches and Technical Drawings

Technical sketches are the backbone of any tech pack. These are flat, no-nonsense drawings - no fancy shading, just the facts.

Usually, designers use Adobe Illustrator or some CAD tool. You’ll see front, back, and side views - clean lines, true proportions.

Seam and topstitch placement

Pocket style and location

Zipper and closure spots

Trim and hardware details

Callouts with leader lines point to details, referencing notes elsewhere in the pack. These aren’t fashion illustrations—they’re all about accuracy, not art. Every line means something real for the factory.

Bill of Materials and Materials Specifications

The bill of materials (BOM) spells out every single thing needed to build the garment. It’s your insurance against production hiccups and budget surprises.

Main fabric specs should include things like fiber, weight, weave, and finish. For instance: "100% Cotton Jersey, 180 GSM, Pre-shrunk, Enzyme Wash."

Main fabrics and linings

Trims - zippers, buttons, elastic, etc.

Thread - colors and types

Labels and hang tags

Hardware - grommets, snaps, you name it

Each item lists the supplier, color codes, and where it goes. Pantone references help keep colors consistent. Most designers use a table layout - description, quantity, color, supplier - to make sourcing less of a scavenger hunt.

Construction Details and Notes

Construction details are the how-to guide for putting the garment together. The more specific, the better - factories really appreciate not having to guess.

Stitch types (overlock, flatlock, cover stitch)

Seam allowances and finishing

Pressing instructions

Quality standards and tolerances

Notes might cover special techniques - like how to attach a pocket or install a zipper. Sometimes, a little extra sketch helps clarify tricky spots.

Thread specs should match each construction area. If you want contrast stitching, call out the color and stitch length. These details help factories plan ahead and avoid surprises.

Size Specifications and Grading

Size specs lay out the exact measurements for every size. Nail this, and you’ll save yourself a lot of sample headaches.

Body length and width

Sleeve length, armhole circumference

Neck opening, shoulder width

Hem and cuff specs

Grading rules show how each measurement shifts between sizes maybe chest width grows by 1 inch, sleeve by 0.5 inch, and so on.

Tolerances set the wiggle room for factory measurements. Usually ±0.25 inches on small stuff, ±0.5 inches on bigger ones. Designers use a grading table sizes in columns, measurements in rows so factories can check any combo at a glance.

The Tech Pack Workflow: From Creation to Production

Creating a tech pack isn’t just about filling in a template. It’s a process, with the right tools, lots of back-and-forth, and plenty of tweaks along the way. Success really depends on how teams talk to each other, how feedback is handled, and whether everyone’s using the right software to keep things on track.

Tools and Software for Developing Tech Packs

Adobe Illustrator is still the go-to for pro-level tech packs. It’s great for technical sketches, diagrams, and measurement charts if you know your way around it. Platforms like Techpacker are built for this stuff, with templates, tables, and tools for collaborating with your team or your factory.

PLM (Product Lifecycle Management) systems take things further, tying tech packs into bigger production workflows - think version tracking, approvals, all that project management jazz.

Software Type | Best For | Key Features |

Adobe Illustrator | Detailed sketches and diagrams | Vector graphics, precise measurements |

Techpacker | Streamlined tech pack creation | Templates, collaboration tools |

PLM Systems | Large-scale production | Version control, team coordination |

Honestly, most designers mix and match - sketches in Illustrator, then assemble everything in Techpacker or a PLM tool for easier sharing and updates.

Collaboration Among Teams and Stakeholders

Product developers are the middlemen, making sure designs are doable and spotting production headaches before they happen. Design teams bring the creative juice, while technical folks turn those ideas into specs factories can actually follow. Quality control teams set the bar for testing and compliance - what’s good enough, what’s not. They define the tolerances for fit, construction, and materials. Regular meetings help keep everyone on the same page. And with so many cooks in the kitchen, version control is huge - use clear file names and track changes, or you’ll end up with a mess.

Sampling, Feedback, and Error-Free Samples

Sampling is where the tech pack gets put to the test. Factories make a prototype based on your instructions - this is your chance to catch issues before they turn into expensive mistakes.

Error-free samples don’t just happen. There’s a feedback loop - brands and factories go back and forth, checking fit, construction, and materials against the specs. Fit sessions with real people can reveal issues you’d never spot on paper. Document any changes and update the tech pack as you go.

It’s totally normal to go through a few rounds of samples. samples, technical designers check things like seam construction, drape, and Each one should fix the last round’s problems, but keep the original design and production realities in mind. When reviewing finishing - comparing everything to the tech pack to make sure the factory’s on the right track.

Communication With Clothing Manufacturers

Clear communication is key if you want to avoid production delays or quality hiccups. Apparel manufacturers really need a direct line to the technical folks for any spec clarifications. Without that, things can get messy fast. Regular production meetings - are actually useful for talking through timelines, material issues, or construction snags. It’s better to hash out problems early than scramble at the last minute.

Manufacturers sometimes pitch alternative construction methods or materials, depending on what they’re set up to handle. Technical teams have to weigh these ideas carefully, making sure they don’t mess with the design or push costs up too much. Keeping a record of all these conversations - emails, meeting notes, spec updates - matters more than people think. Organized documentation helps everyone stay on the same page, especially when you’re juggling multiple production runs. Garment production is rarely set-it-and-forget-it. Tech teams need to stay available during manufacturing, ready to answer questions or sign off on last-minute tweaks.

Best Practices and Tips for Fashion Tech Packs

Accurate costing really hinges on detailed tech packs that spell out every material and construction method. When you bake quality control into the tech pack, you catch most errors before they get expensive - and it’s a lifesaver for keeping fit consistent across sizes.

Costing and Pricing for Garment Production

A solid garment cost sheet needs precise measurements and clear material specs straight from the tech pack. Factories rely on this info to figure out fabric usage, labor hours, and trims - otherwise, you end up guessing. Don’t skip detailed fabric maps with exact yardage per piece. It’s a hassle, but it keeps you from blowing the budget on surprise material costs during the costing and pricing process.

Essential costing elements include:

Fabric consumption per size

Trim quantities and specifications

Construction time estimates

Labor complexity factors

Manufacturers can’t give you a real quote without a full Bill of Materials (BOM). Leave out details, and you’re almost guaranteed cost surprises down the road. Don’t forget interfacing needs or special construction notes - they can seriously affect both material costs and how long things take to make.

Ensuring Fit and Quality Control

Fit quality comes down to having spot-on measurements and clear grading between sizes. Tech packs should always include Points of Measure (POM) diagrams so there’s zero confusion about where to measure. Technical designers suggest adding measurement tolerances for each spec. It’s a small thing, but it saves you from fit disasters when factories are working within the allowed range.

Quality control measures include:

Detailed construction callouts

Stitch type specs with ISO codes

Seam allowance requirements

Finishing instructions

Fabric maps help sample makers figure out which materials go where, cutting down on construction mistakes and helping the fit through tricky areas like the torso and sleeves. For complex construction, toss in photos of similar garments. Sometimes a picture really is worth a thousand words - especially when you’re trying to avoid miscommunications.

Maintaining Consistency Across Collections

Keeping your fashion tech packs consistent just makes life easier for everyone - especially the factory teams who need to grasp specs fast. Stick to the same measurement codes and construction terms throughout your collections. It might feel tedious, but trust me, it saves headaches later. Set up symbol libraries in your design software for anything you use over and over. That way, if you tweak a symbol, every tech pack updates without you hunting down stray versions. It's a small upfront effort with a big payoff.

Consistency requirements:

Standardized measurement terminology

Uniform labeling and packaging instructions

Consistent thread color specs

Matching construction methods

Always keep revision histories right on each tech pack page. It’s a simple habit that helps everyone see what’s changed and makes sure nobody’s working from outdated info during the production process. And don't forget to number your pages clearly (like 1 of 10, 2 of 10) - otherwise, things can get lost in the shuffle as packs move between departments.